Connect with us

Published

1 month agoon

By

admin

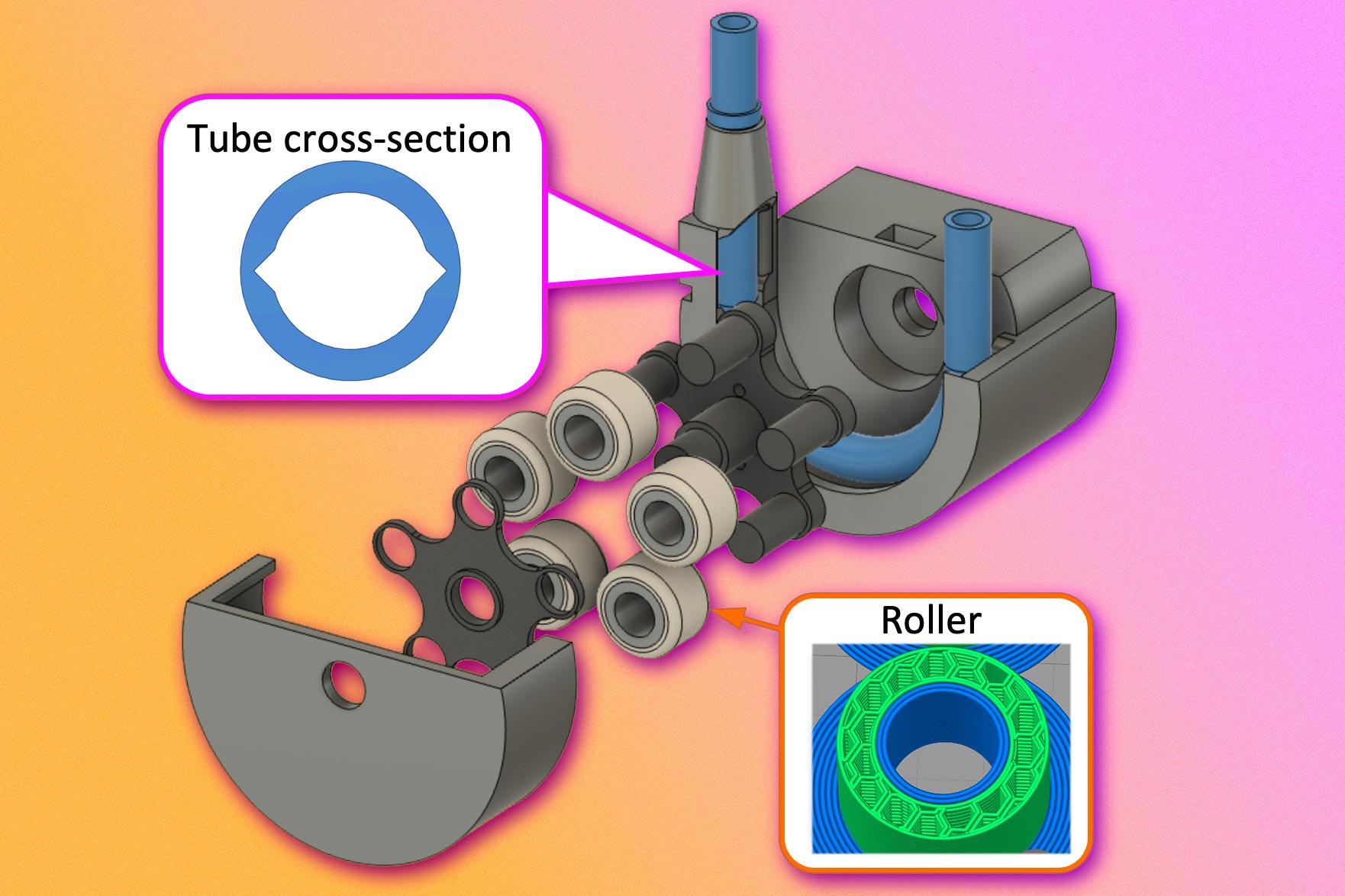

MIT researchers have developed a 3D-printed miniaturized peristaltic vacuum pump, crucial for portable mass spectrometers that can monitor pollutants, conduct medical diagnoses in remote areas, or test Martian soil. This innovative device, the size of a human fist, features a tube made of hyperelastic material with notches that minimize traditional design issues, reduce friction, lower heat generation, and extend operational lifespan. Portable mass spectrometers are essential tools for applications such as analyzing drinking water safety or detecting toxins in blood, but their effectiveness requires reliable and inexpensive vacuum pumps.

By utilizing additive manufacturing, the researchers addressed common failures in conventional pumps, achieving a vacuum pressure significantly lower than that of existing diaphragm pumps. The unique design allows fluid and gases to move without leakage, enhancing functionality, and facilitating higher quality analysis. The entire structure can be printed in one pass, eliminating post-assembly defects. Future enhancements aim to further decrease operational temperatures and integrate the pump within a complete miniaturized mass spectrometer. The research highlights the capacity of 3D printing technology to innovate and reduce costs in creating advanced analytical tools, marking a significant advancement in instrumentation design.